Chewing gum is a fun snack that most folks love. Ever wondered how chewing gum is made? So there is quite a bit of a complicated process that goes into chewing gum production. Ohayoo, suitable for recipe serving,Our highly specialized equipment forms a cohesive system that significantly reduce the chewing gum production process, thus ensuring that your operation is as painless and cost-effective as you want it. Let’s explore how integrated machinery has the ability to maximise the production of chewing gum.

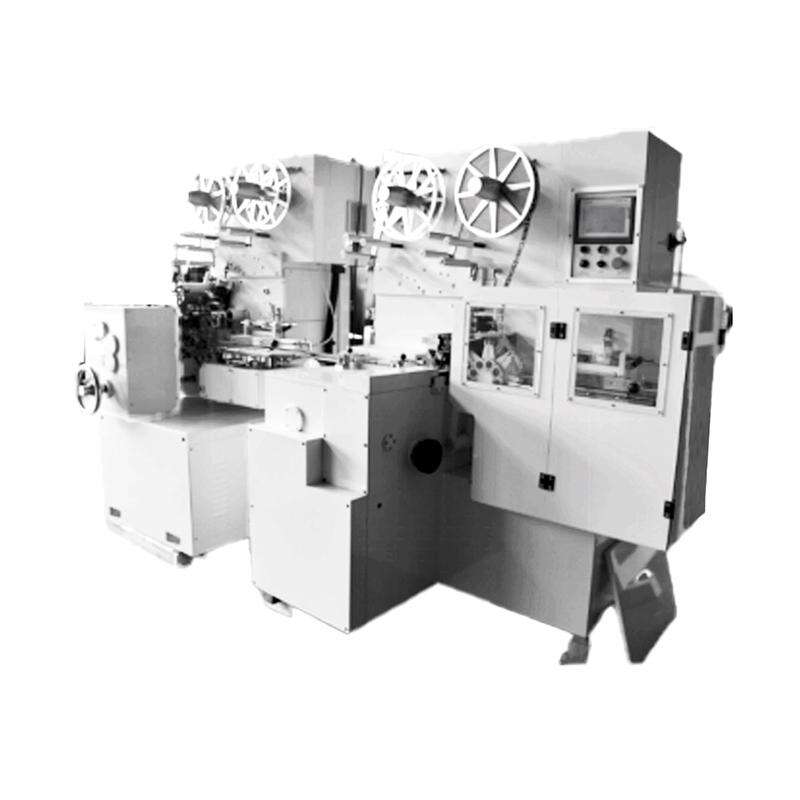

Production of chewing gum equipment The efficiency with the manufacture of chewing gum is greatly improved through the use of integrated equipment. Its integrated lines contribute significantly in time- and resource-savings by consolidating various manufacturing processes into one system. In other words: A larger amount of chewing gum can be manufactured within a fixed time period, which results in a situation of higher productivity as well as lower manufacturing expenses. By combining machines, from mixing, extrusion to cooling, it is possible to prevent therefore the errors or breakdowns and it is not necessary to use many machines.

Golden Orient Machinery is always refreshing and updating its gum machinery integrated productionequipment. Our integrated equipment comes loaded with the industries latest technology and innovations to provide top-quality performance and dependability. Offering superior mixing and forming, as well as better cooling and packing capabilities, our equipment performs with high performance features to yield chewing gum of the highest quality. With our newest developments with regard to integrated systems, producers operate with even more exactness, steadiness and efficiencies when processing rubber in the production of gum.

Chewing gum manufacture, like all processing, is balanced on the knife-edge of consistency. Manufacturers whose production line uses Golden Orient Machinery equipment can be confident that every batch of the chewing gum they produce is of the highest quality. Our combination machine is engineered to provide predictable outcome by managing temperature, pressures and agitating durations. This keeps all of the gum consistently-textured, consistently-flavored, and consistently-colored. With stringent quality control at every stage of production, our integrated machinery assures that only high quality chewing gum is provided to the customers.

Not only does the integrated equipment guarantee top-notch quality, it also brings economic benefits to gum manufacturers. Our integrated systems are designed to maximize system performance and, in turn, drive down cost-per-part and increase your bottom line. By means of processing economy and minimum idle time, it is in this way, that this leads to a less expensive manufacture of more gum. This can result in higher profit margins and a competitive advantage in the market. Whether you have long service printing line, investment for the whole set of equipment from Golden Orient Machinery can reduce your cost and bring you high quality of production.

A major benefit of integrated equipment is the increased amount of flexibility and innovation it permits for chewing gum production. Featuring flexible design and settings, this combination of process equipment provides manufacturers with the resources needed to produce gum products that are truly unique to personal tastes and market goals. Pushing the envelope: Whether it's flavour, texture, shape or a combination of all three, our processing options feature the flexibility you need to explore new opportunities in the gum market. By stimulating creativity and innovation, Golden Orient Machinery integrated equipment enables manufacturers to keep one step ahead and respond to new trends and demand from food and drink companies in the fast moving market.