Chocolate is a very popular food enjoyed by people in practically every corner of the globe. It takes special machines to make chocolate treats that look nice and taste good. One of such equipment is known as chocolate enrober. These are machines that coat candies, cookies or other foods with a thin layer of chocolate. It makes sweets shiny and smooth, and it saves so much time versus doing them by hand. Golden Orient Machinery creates this type of equipment, and our Chocolate Enrobing Machine are designed to run well, last for a long time and allow the chocolate maker to make their product better and faster.

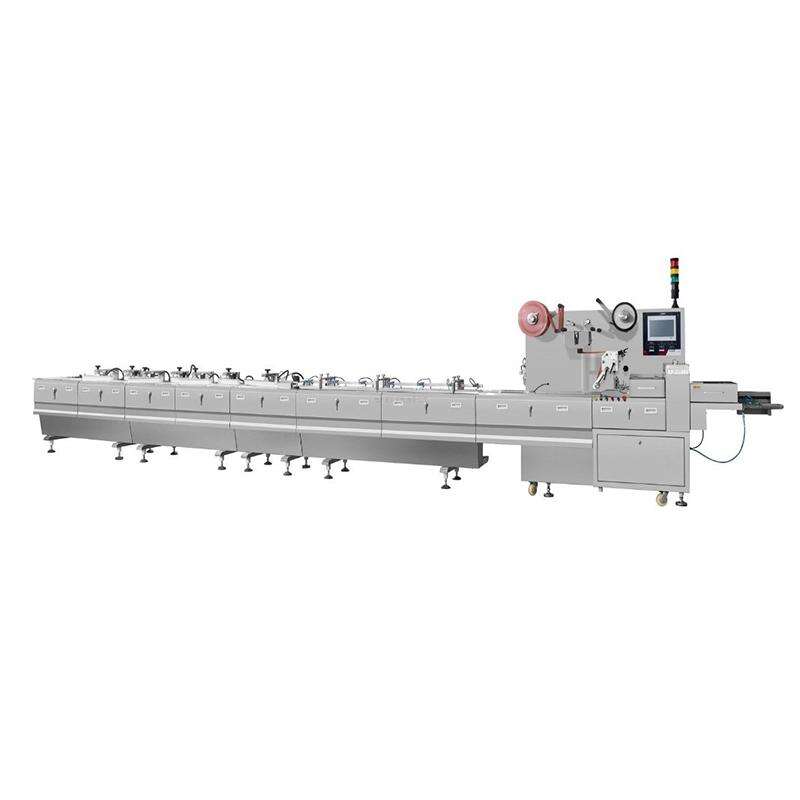

Chocolate enrobing machinery is a device that coats food with chocolate uniformly and in large quantities. For instance, you want to coat a cookie in chocolate. Rather than hand-dunking each cookie, this machine sprays or coats the chocolate on dozens of cookies at once. It operates by passing the food on a conveyor belt through a curtain or spray of molten chocolate. Chocolate cascades over food, even on the sides. Next, the coated treats are transferred to a cooling area where the chocolate sets and hardens perfectly. The machine monitors the temperature of the chocolate closely, because if it is too hot or too cold, the chocolate will not coat neatly or be shiny. Enrobing machines from Golden Orient Machinery employ clever means to ensure that chocolate is at the optimal temperature. These devices are also adaptable to receive food products of varying sizes and configurations. If a chocolate bar is denser, or the biscuit is smaller, for example, it can cope perfectly well with that. That versatility is especially helpful for chocolate makers who want to make a variety of treats. Plus, the machine is constructed of rugged materials that can be cleaned with ease — vital for food production to makes sure everything in it remains safe and tasty.

Chocolate enrobing equipment alters how products come out in so many good ways. For one, the chocolate layer appears smooth and nondescript, which is more pleasant to look at. With the hand application, chocolate is thick in some places and thin in others, but with this machine it’s going to be consistent. Golden Orient Machinery’s chocolate tempering and enrobing machines also speeds production. Where workers once dip or coat sweets painstakingly one by one, the machine does dozens at a time. This reduces the time that would be required to put out large lots. It also entails less error and waste, the chocolate is used judiciously and doesn’t drip or spill too far. Another benefit is hygiene. Rules on food safety are extremely strict, and machines cut the risk of contamination by minimizing how many people touch the product. Our coating machines are designed to keep the chocolate clean and free of contaminants throughout the entire process. And the machines can work around the clock for long periods without fatigue or error — far beyond human capability. This is ideal for chocolate makers who plan to expand their business or try to keep up when they are flooded with orders. The machines accommodate various chocolate coatings — milk, dark or white chocolate, even layers if desired. This allows chocolatiers more flexibility in developing new recipes or designs. At Golden Orient Machinery Ind, we understand the value of our customer's needs through quality machines to produce great products which is why we build each every machine with heart & soul.

Chocolate coating machinery is essential to producing high volumes of chocolate products both fast and with quality. And when a chocolate company wants to make lots of chocolates each day, doing so manually can be slow and error prone. That’s what machines like ones from Golden Orient Machinery are for. These are devices encasing candies, cookies, or other treats in a silky sheath of chocolate. This process is called enrobing. It helps the chocolate adhere evenly to the product so it looks good and tastes good.

Chocolate enrobery gear is money saving and time. The Chocolate Enrobing Machine With Cooling Tunnel works faster than people, so more of the chocolates are made in a shorter time. And it is also consistent in its chocolate layer, which is always the same thickness, so that each piece is just right. This consistency is important, because consumers want their chocolates to look and taste the way they have come to expect each time they make a purchase. If the chocolate is too thick or thin, it can alter the taste, or cause the chocolate to break.

Another reason that these machines are necessary is because they keep the chocolate at the proper temperature. Chocolate is a substance that melts when it gets too hot, and then hardens when brought back down to cooler temperatures. Golden Orient Machinery’s enrobing machine is equipped with specific controls in place to ensure the chocolate remains at a pure state and high enough quality to coat products. That means less waste and better chocolate quality.

First, you will want to clean the machine on after each use. Chocolate can freeze up and clog some of the machine if there are any remnants left inside. To clean, the machine is typically turned off and cooled. Next, factory workers remove the excess chocolate from the sections that come into contact with the chocolate and products. The machine is carefully cleaned with warm water and special cleaning instruments.