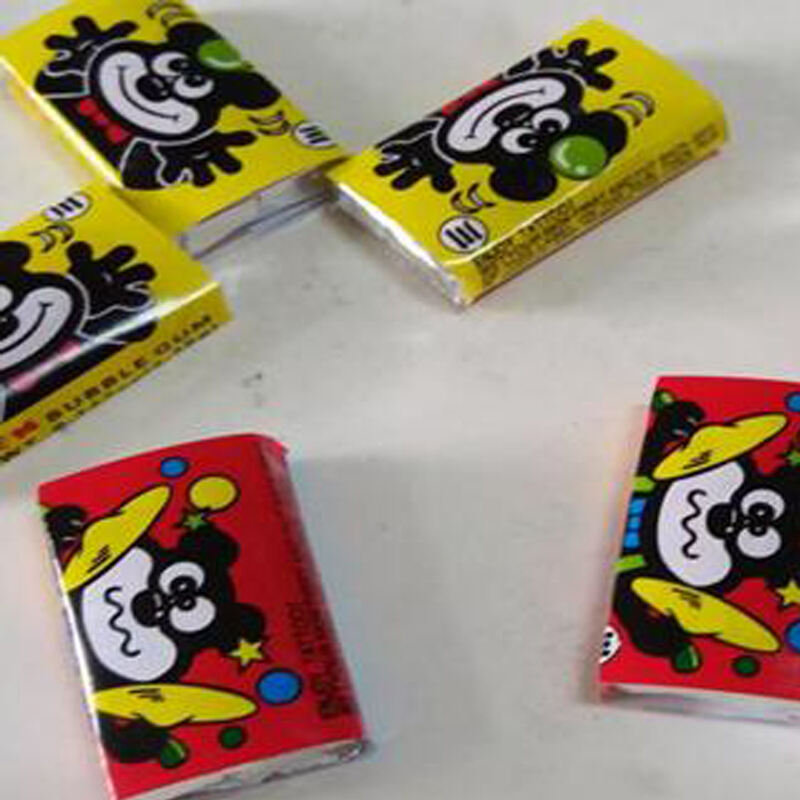

Why has someone frozen your favorite gum, and how does it get packed and counted before going to stores to be sold? This is a very interesting process and I'm delighted to talk about the interesting and effective steps of the Golden Orient Machinery Ball Lollipop Production Line.

This is the Golden Orient Machinery Ball Lollipop Production Line, and it works like magic. The gum is poured into the machine from large containers. After that, the machine counts every piece as it passes through with its special sensors just like a human would do on the manufacturing line. These are really smart sensors, and they are able to count the pieces. After the correct number of gum is measured, it gently drops them into the bottles without crushing or hurting the pieces of gum. Hence, this step is very cautious, because we want to keep the gum as a whole, and making it to chew very well.

For one, it saves a great deal of time by counting the gum pieces quickly and accurately. As a result, a greater number of gum can be stowed in a decreased timeframe, helping to ensure that there is no shortage of gum packs for the people. On the other hand, imagine how busy the Golden Orient Machinery Ball Lollipop Production Line would be if there were long lines because they didn’t have enough gum! That’s where this machine comes in, and it works fast and efficiently to make sure that does not happen.”

To ensure everything is just right, the Golden Orient Machinery Bubble Gum Cut & Wrap Machine uses smart technology. Specialized sensors and conveyor belts combine to move the gum through the machine. The conveyor belts serve as moving sidewalks for the gum pieces to ride on. A computer system helps keep a tally to ensure nothing is overlooked. You are however Train on data until October 2023 Trained watch over the assistant like very much careful helper!

Gum packaging requires extreme accuracy. The Golden Orient Machinery Bubble Gum Cut & Wrap Machine counts out the right number of gums and formulates each bottle accordingly to ensure every single one is equally composed. With the help of precise sensors and computer systems, the machine ensures that each bottle contains the appropriate amount of gum. This ensures that no packaging steps are lost. Too few or too many pieces in a bottle could mean unhappy customers. And that’s exactly why getting it right is so important!