Many people all over the world love eating candy. It has so many different flavors, shapes, and colors, which makes it fun for everyone. Have you ever wondered how these confectioneries are prepared? Lexie will teach us about the machines and tools that are used to create candy today. We have good equipment for candy makers to help them make yummy treats easy and fast At Golden Orient Machinery.

Making candy: There were some important steps and special machines to ensure that the candy was tasty and of good quality. Candy production uses some of the oldest machinery in the food industry—cookers, mixers, formers, and packaging machines. Each of these machines does a particular task. For instance, cookers heat up the food stuff to just the right level of temperature so that they can melt and mix properly. Mixers to mix the ingredient to ensure everything is well-blended. Formers give the candy it is final shape, and packaging machines prepare the candy to be sold to the public. Together, these machines function as a team to convert raw substances into the delicious treats we all love.

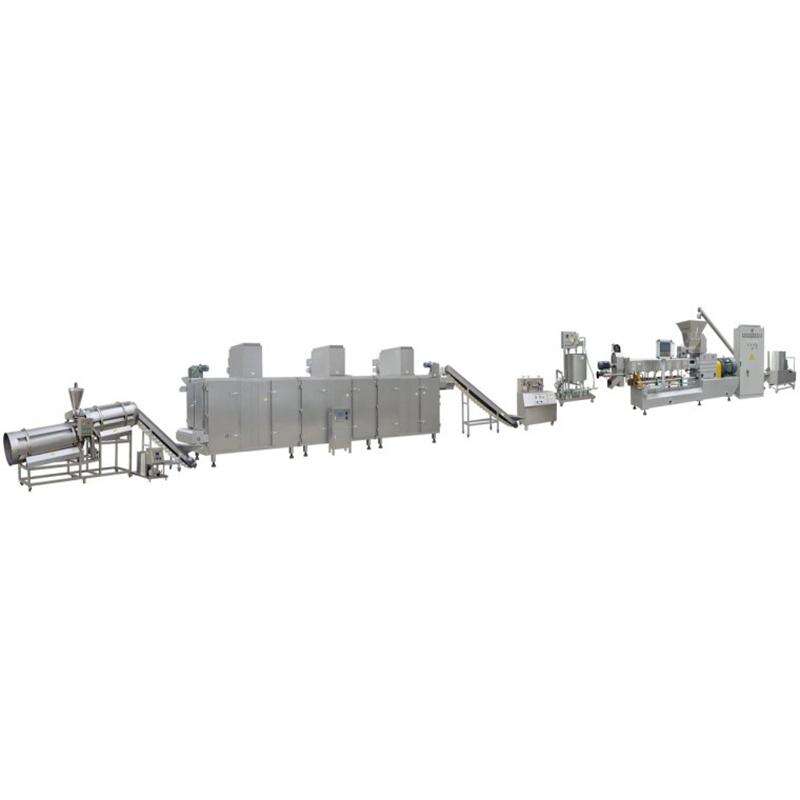

Mix and blend machine play a very significant role in candy making process. These Golden Orient Machinery Candy automated production line machine combine various elements such as sugar, flavours and colours to provide the perfect candy mix. The first step is to mix all the ingredients in the mixer. Once the ingredients are inside, the machine starts blending them. By closely monitoring the mixing, candy makers ensure that every batch of candy will have the same taste and texture as the previous ones. This makes every piece of candy just as delicious as the previous.

Candy making, obviously, also involves controlling the temperature. And different candies require different degrees of heat to reach the right consistency. Hard candies, for example, have to get hot to solidify correctly. That means they have to be cooked at a high temperature for a period of time. Conversely, soft candies require cooler temps to maintain their chewyness, and not become one with the rock it will be when it reaches it is melting point. Golden Orient Machinery Candy makers along with candy bar packaging machine turn out all sorts of delectable denizens of any candy land, so long as you have the right temperature control machines. This temperature control makes sure each candy is properly made, like it was supposed to be.

The candy mix, once combined, cooked and flavored, is cooled and formed. Cooler machines rapidly cool the candy to keep it from sticking together or becoming too soft. This part is super important because if the candy is too hot, it can come out malformed. The role of shaping machines is to give the candy it is special shape and design. Some candy coating equipment create simple shapes like circles while others make more elaborate designs. Using a variety of cooling and shaping machines, candy makers are able to produce countless different kinds of candies, in countless different shapes, sizes and flavors to suit all types of candy lovers.

After the candy has been shaped and cooled, it is prepared for packaging. Special packaging machines wrap each piece in a way to protect it and keep it fresh. But the Candy equipment also label and seal the candy, so it arrives to people in pristine condition. Food packaging plays a major role as it prevents exposure of the candy to air and moisture, which will spoil the candy quickly. Using good packaging equipment can simplify the production process for candy manufacturers and deliver great goods to consumers. This way, when you purchase candy, you know it will taste as fresh as the day it was made.