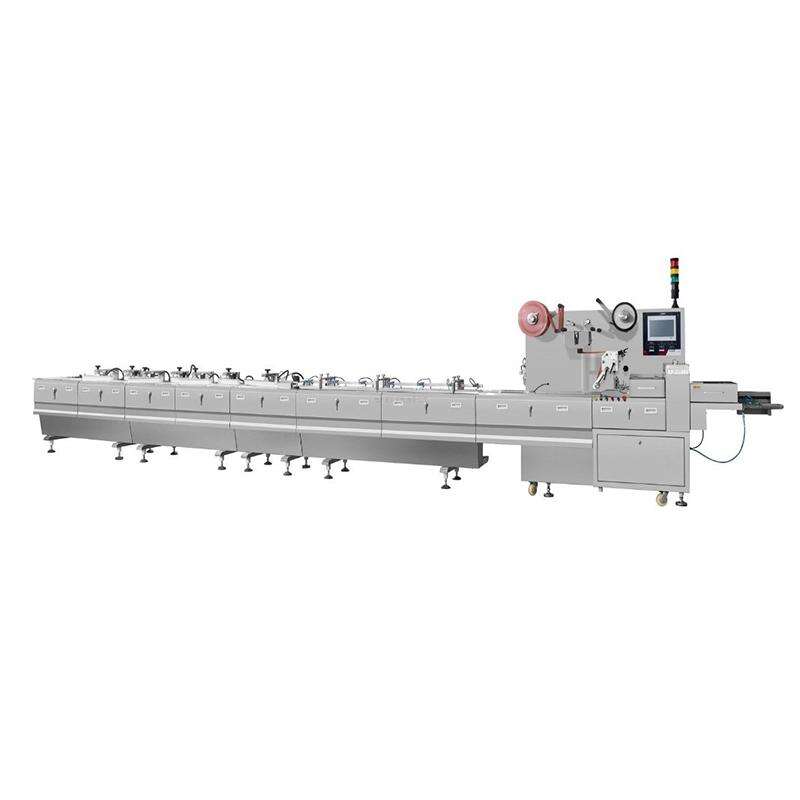

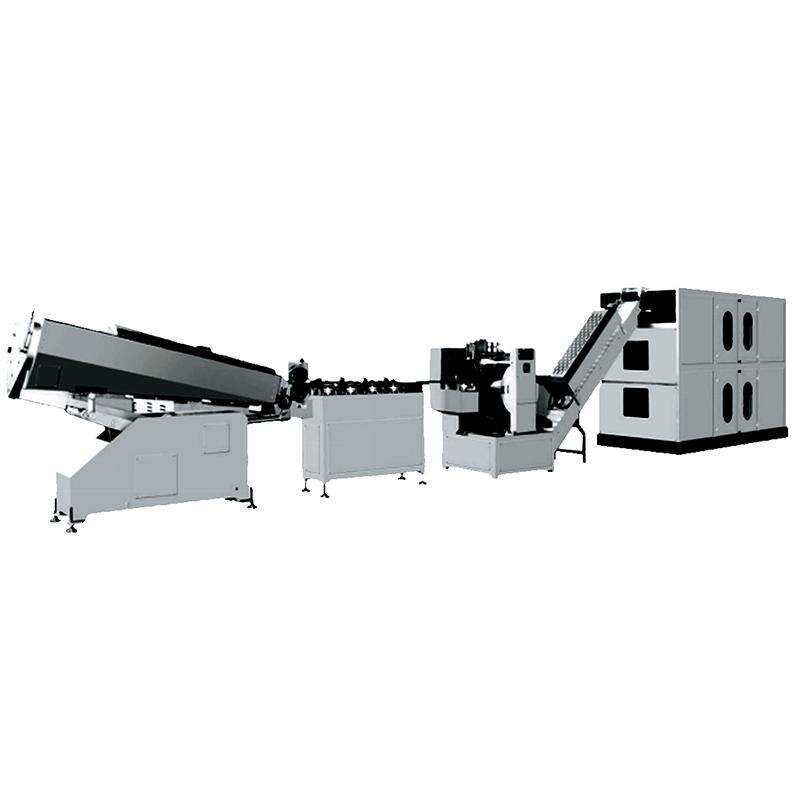

It's a machine to be used for wrapping chewing gum products that allows food production companies save time and charges since the process will now become automatic. The latest generation of automated gum wrapping machines offers your business increased production rates and superior packaging quality. The chewing gum industry uses the following types of machines: Extruder-guillotine cutting machine This equipment is used to feed and cut soft. The automatic chewing gum wrapping machine is for the purpose of packaging a lot of kinds shaped or small size products, such as chewing gums. Such machines package single gum pieces or packs in exactly the same way and at the same speed; each product thus being wrapped sealing and labelled accordingly. Automating this enables companies to mitigate the risk of inaccuracies and operate more efficiently. Thanks to our breakthrough wrapping machine, clients can ramp up production and keep up with demand without sacrificing quality.

Golden Orient Machinery is the reliable source of premium stick chewing gum packing machines. They’re also designed to last and include many state-of-the-art options that can help you maximise your packaging operation. From automatic feed systems to variable wrapping speeds, their machines are tailor made to service the various requirements of chewing gum producers. Golden Orient Machinery’s wrapping machines may offer a new perspective for companies to reduce their packaging costs and secure the edge in the rapid world of chewing gum. Why use an automated chewing gum wrapping machine from Golden Orient Machinery Using our automatic chewing gum wrapping technology provides a number of advantages for your business in the gum manufacturing market. One result is greater efficiency. Automated wrapping machines allow companies to wrap gum at speed multiple times as high, then it is possible with manual wrap, saving time and money. This results in greater gum production in less time, increasing productivity and profits.

Automated chewing gum wrapping technology also provides consistent, high-quality products. Companies can also wrap the gum with a machine, which allows each to be wrapped in equal fashion, compared to doing it by hand. This may be useful to improve brand image and customer value of the chewing gum that eventually will result in high purchase intension and satisfaction from customers.

Inconsistent wrapping An issue that automated chewing gum equipment machines commonly address is the variability in wrapping. When gum is wrapped by hand, a continuous piece of gum may be wrapped in various ways which also makes the wrapping uneven and unprofessional. Machines automatically wrap all gum so that every piece comes out the same - consistent and high quality.

Moreover, automatic chewing gum packing machine can contribute to reduce errors and redo work so that there is no need for labor or costs to correct wrapping. The inventive packer provided with a reliable trolley-type product leaves conveyor which ensures smooth moving of the packs. By achieving reliable, high quality wrapping, they will enable business to save money and time that would be spent fixing problems and explaining failures to customers.